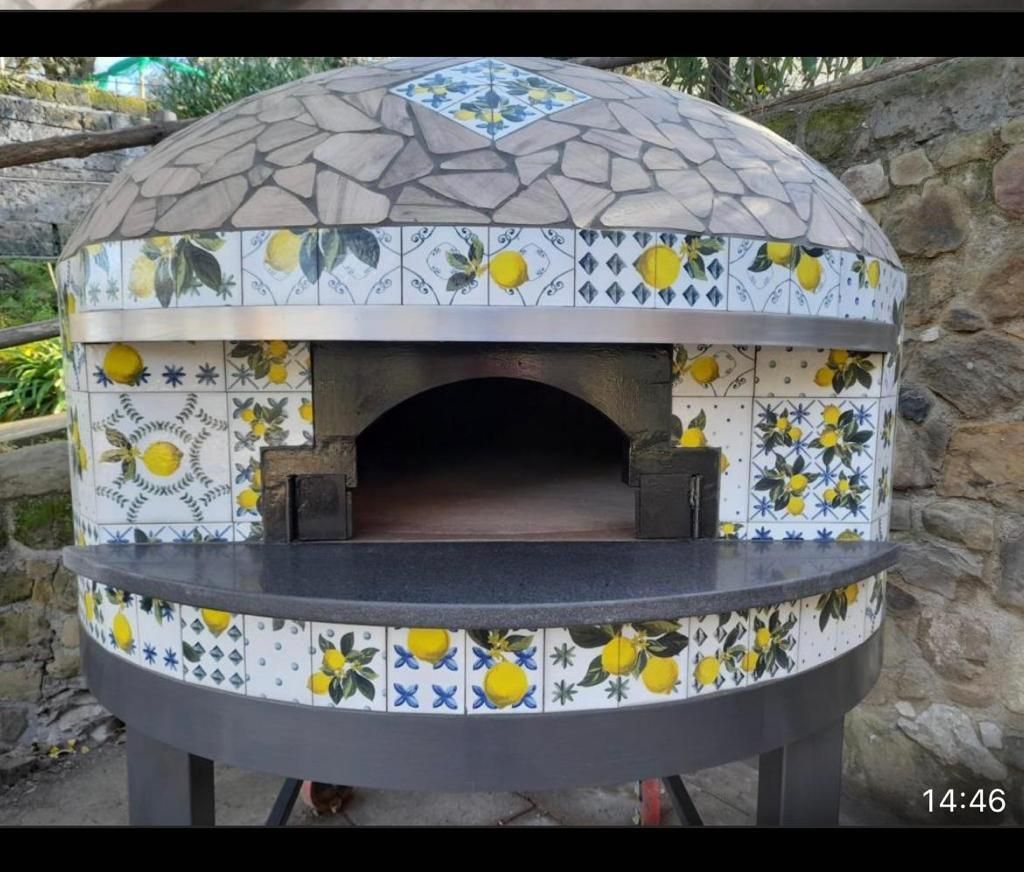

About Forni Aversa

Meet the last two generations of Forni Aversa.

Grandpa kept traditional craftsmanship alive for more than half a century. Although he is no longer with us, his grandson Attilio has learnt all the tricks of the trade.

The little village of Maiano on the Sorrento peninsula is home to the unique stone slabs known as biscotti di Sorrento.

This unique material goes back to the 15th century and is famed for its use in the world's greatest wood-fired ovens. Attilio Massa has followed in the footsteps of his grandfather and kept the name of Forni Aversa alive.

In December 2015 we were awarded the title of "master craftsmen", in recognition of the quality of our historic product and the wood-fired ovens made with Maiano's famous stone slabs.

We are one of only two potteries in the world that still make biscotti.

Just 60 years ago there were seven of us, providing work for dozens of families. We were part of one of the most productive sectors on the peninsula. At Forni Aversa today, we make stone slabs and oven bases for bakeries and pizzerias around the world.

Our biscotti and other stone slabs can be found on every continent and in over 100 countries.

Every year our craftsmen turn out thousands of stone slabs for building wood-fired ovens in Italy and around the world.

a tradition and a guarantee

From our kilns come stone slabs destined for the ovens of the best pizzerias around the world, from Little Italy and Broadway in New York to London and Paris.

Restaurant and pizzeria owners in Italy count themselves lucky to have got hold of stone slabs made by the Aversa family in our artisan oven materials workshop near Naples. In Rome, Florence, Milan, Venice and Turin, the pizzas made on our stone from Sant'Agnello are always the tastiest.

We extract our raw material right on site. Following a centuries-old process, the clay is carefully sifted and mixed with water, then worked by hand on old wheels to refine it. Later on it is placed in wooden frames built by our forefathers.

Before they are cooked in the historic wood-fired kiln at 800ºC, our stone slabs are left to dry for a few months in summer and for two months in winter.

one material, so many solutions

Our stone slabs from Sant'Agnello stand out from other materials made in mechanical presses and modern machinery, among other things for their porousness.

This feature makes the slabs resistant to high temperatures. We produce a wide range of products, from oven bases to cladding.

The range of forms it offers, its perfect combination with different materials and their versatility when used in classic or modern décor, are what allow our famous cotto maianese to create and personalise any living space, be it an elegant house in the country or a more practical urban flat.

why biscotto di sorrento?

- Clay - Earth rich in volcanic silicon and pumice, a particular feature of the land under Sorrento's famous citrus groves.

- Porousness - The clay makes our biscotto di Sorrento very porous. An oven base must be porous if it is to heat up quickly and conserve its heat for a long time, releasing it pleasantly and uniformly. The essential difference between biscotto di Sorrento and the other stone slabs on the market is that it does not burn the bottom of the pizza, but absorbs the humidity from the dough.

- Craftsmanship - Here at Forni Aversa we respect the following historic, traditional production methods:

- After manual extraction, the clay is carefully sifted and mixed with water in mixers.

- The clay is then placed in wooden moulds, which are shaped like the desired product (stone slabs, oven bases, tiles).

- These slabs are then left to dry naturally for about 30 days, then stacked and left to dry again for 10 days.

- As soon as the slabs take on a light-grey colour, they are ready to be stacked in the kiln, to dry for another seven days.

- Finally, the kiln is cut and closed and the natural baking begins. This involves seven hours of burning wood.

- After four days of baking, the slabs are ready, having taken on a natural red colour.